The JM provides little information concerning undercoating and paint. Appreciate some guidance on the application and type of undercoating front and rear and the paint finish on the radiator support blacket located in the front wheelwells and the access panels on the forward side of the rear wheelwells. Thanks Clark Erlandson 18941

Wheelwell Surface Finish - 1970

Collapse

X

-

Re: Wheelwell Surface Finish - 1970

Clarke, There really is not much under coating on the wheel wells, generally the tops of front fenders and at the rear of the front fenders, No two car were the same so some may have more area coverage. the blackout is much the same a low gloss paint painted in the front, tops, and rear wells on front, as for the rear wheel wells the under coating was on the tops of the wheel wells, and rear splash panels its generally the thickest of the whole car and if you car has seat belt shoulder harnesses those brackets had undercoating on them.

The radiator lower support bracket was painted a semi to low gloss black, the acess panel in front of rear wheel wells were painted the same.

If you cars wheel wells has been untouch since the factory did it look closely at it and just copy it. or even better use a good cleaner and just clean it up. theres nothing like the original. I may even be touched up after cleaning.New England chapter member, 63 Convert. 327/340- Chapter/Regional/national Top Flight, 72 coupe- chapter and regional Top Flight.- Top

-

Re: Wheelwell Surface Finish - 1970

Actually the factory used a product that was manufactured from a company called Allied Corporation. It was aplied on the rear verticle portion of the rear wheel wells and also the mount for the seat belts. The front wheel wells were only covered on the rear verticle portion of the well. An interesting note is that if you observe Bowtie/Survivor Corvettes, about 1" or 2" from the bottom lip on the front wheel wells is where there is no undercoating used. I can appreciate what Clark said regarding that it was the same coating as the radiator suppor, but that coating was not as thick, but rather kind of gummy to the touch. I am speaking from my experience as I not only did the research, but I was able to purchase 95% of all paints/coatings from the original suppliers of the era that were used on most C2 and C3 Corvettes.

- Ron"SOLID LIFTERS MATTER"- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

Hi Clark,

I found a similar amount of black-out on my 71 as Ron described.

There appeared to be no black-out on the upper surface of the wheel-well, (the underside of the hood surround); nor was there any on the inner side of the front fender, including the bonding strip area.

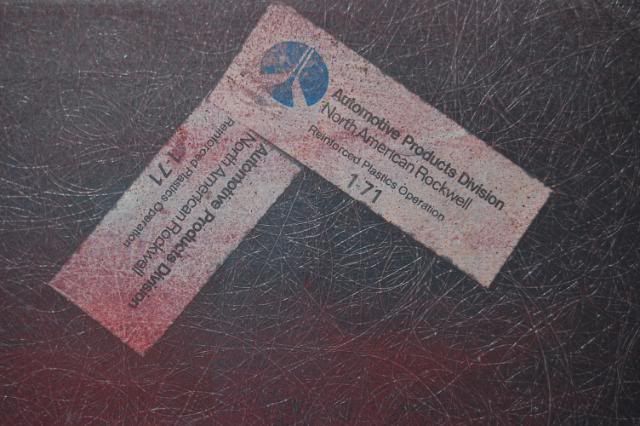

I was using simple green to remove the road grime in the wheel-well and did find these labels embedded in the hood surround fiberglass. My 71 is a mid-January built car.

Hope this helps a bit!

Regards,

Alan

71 Coupe, 350/270, 4 speed

71 Coupe, 350/270, 4 speed

Mason Dixon Chapter

Chapter Top Flight October 2011- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

Thanks Guys...The body shop the painted the car cleaned the wheel wells to the base fiber glass leaving no "clues" as to the original finishes. Your comments fit well with what I remember from owning this car for 40 years. Unlike so many other refinishing issues it's nice there was no set finite pattern for applying the undercoating. Boy, what you learn from doing the first restoration!- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

Clark,

Follow the link in my signature below to photos of my original 1972. There are some good pictures of the undercoating and blackout if you wish to look for them.Vice-Chairman (West), Michigan Chapter NCRS

71 "deer modified" coupe

72 5-Star Bowtie / Duntov coupe. https://www.flickr.com/photos/124695...57649252735124

2008 coupe

Available stickers: Engine suffix code, exhaust tips & mufflers, shocks, AIR diverter valve broadcast code.- Top

Comment

-

- Top

Comment

-

- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

I guess I will need to do some more checking. I just called the store, gave them the 3M part number that Dickie posted (8964) thinking I would be getting aerosol cans and when they came they are the shape of an aerosol can only larger. You poke a hole in the top and attach the applicator which you need to hook up to air pressure.- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

Hi Russ,

I've been using 3M #08881 rubberized undercoating which does come in an aerosol can.

It's a bit thin so I put it on in several coats with drying time between them. I found I can vary the texture by how far from the surface I hold the can. (The further away, the larger the 'pebble'). It does splatter a bit so I do some protective papering first.

Have you seen 08881?

Regards,

Alan71 Coupe, 350/270, 4 speed

Mason Dixon Chapter

Chapter Top Flight October 2011- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

Guys...It took flat tire caused by a cut valve stem due to an incorrectly installed PO 2 wheel cover to "remind" me I have yet to refurbish the wheel wells. UGH. This original post was just over 5 years ago. Anyway, one more request for specifics and I'm back at it.

The front wall of each front wheel well has an opening for the outer bumper brace that is covered by a rectangular "rubber" seal shaped to conform to the brace and held to the wheel well by several staples. Was this seal installed before or after the wheel well was painted with blackout? Any overspray on the seal? Thanks...Clark- Top

Comment

-

Re: Wheelwell Surface Finish - 1970

I can say with 100% certainty that the seals for the bumper braces were applied before paint in the body shop. When I stripped the wheel wells of my 70 the seals had red primer, color coat, and then black out.

Interesting thing about my 70 is there was almost NO under coating on the driver's side. Passenger side was typical for an original car. If you can save the under coating do it. It was not really that tough. I am glad I did as you need a special gun to shoot anything close to original under coating.

Kind Regards,

Bill

Guys...It took flat tire caused by a cut valve stem due to an incorrectly installed PO 2 wheel cover to "remind" me I have yet to refurbish the wheel wells. UGH. This original post was just over 5 years ago. Anyway, one more request for specifics and I'm back at it.

The front wall of each front wheel well has an opening for the outer bumper brace that is covered by a rectangular "rubber" seal shaped to conform to the brace and held to the wheel well by several staples. Was this seal installed before or after the wheel well was painted with blackout? Any overspray on the seal? Thanks...Clark- Top

Comment

Comment